The Apron Drive Crystal bridge is the cutting-edge design for passengerboarding bridges. Its free movement in three axes: telescope, elevation androtation, allows the maximum flexibility in aircraft docking manoeuvres whiletaking up the minimum amount of apron space.

ThyssenKrupp Airport Systems Passenger Boarding Bridges (PBB) aremanufactured in the most modern production plants which are equippedfor optimum material flow and which have been specially and exclusivelydeveloped for building PBBs.

The overall concept includes the use of high quality materials, a very highstandard of finishing and a corrosion protection system which has beenspecially developed for high reliability and an above average service life. Theresult: a Passenger Boarding System, which sets new standards.

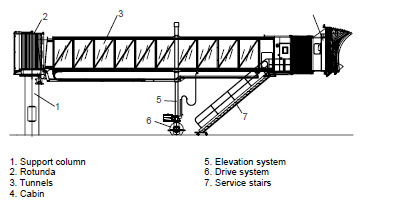

The ThyssenKrupp Airport Systems Apron Drive Crystal PBB consists of the following main components:

The Crystal Apron Drive PBB (ADC) tunnel walls are fully glazed. The characteristics of the glass depend on customer requirements, with a variety of options as to color, lighting and thermal and acoustic qualities.

The hydraulic elevation system provides extremely smooth adjustment operation while also reducing operating costs to a minimum.

Automatic systems, such as Point & Go and pre-positioning, help to automate bridge handling, hence reducing the possibility of human error.

The PBB is available in two- or three-tunnel versions.

ThyssenKrupp Airport Systems Passenger Boarding Bridges are designed and manufactured according to:

EU: European Directives (2006/24/ EC Machinery, 2006/95/EC Low Voltage, 2004/108/EC Electromagnetic Compatibility) and Harmonized Standards (EN 1915-1, EN 1915-2, EN 12312-4, EN 60204-1, EN 61000-6-4, EN 61000-6-2, EN 61000-3-11 and EN 61000-3-12).

The International (ISO, IEC) standard and NFPA upon request and specification.

CHINA: EU Standards & Regulations, GB standard (Chinese National Standard) and MH/T6028 (China aviation industry standard).

USA: USA/CSA codes AISC, AWS, ASTM, SAE, NEMA, NEC, UL, ULc and NFPA upon request and specification.

Two tunnel bridge - crystal

Model

| TBC 14/11-2 | TBC 15/11.75-22 |

| TBC 17/12.5-2 | TBC 18.5/13.25-2 |

| TBC 20/14-2 | TBC 21.5/14.75-2 |

| TBC 23/15.5-2 | TBC 24.5/16.25-2 |

| TBC 26/17-2 | TBC 27.5/17.25-2 |

| TBC 29/18.5-2 | TBC 30.5/19.25-2 |

| TBC 32/20-2 | TBC 33.5/20.75-2 |

| TBC 35/21.5-2 | TBC 36.5/22.25-2 |

| TBC 38/23-2 | TBC 39.5/23.75-2 |

| TBC 41/24.5-2 | TBC 42.5/25.25-2 |

| TBC 44/26-2 | TBC 45.5/26.75-2 |

Three tunnel bridge – crystal

Model

| TBC 23/13.1-3 | TBC 26/14.1-3 |

| TBC 29/16.1-3 | TBC 32/16.6-3 |

| TBC 35/17.1-3 | TBC 38/18.6-3 |

| TBC 41/19.6-3 | TBC 44/20.6-3 |

Parameters

Dimensional characteristics:

| Rotunda | ||

| Internal diameter | 2.44 m | 96.00’’ |

| Free width at the neck of the rotunda | 1.51 m | 59.38’’ |

| Free height at the neck of the rotunda | 2.30 m | 91.44’’ |

| Internal tunnel (tunnel A) | ||

| Free width | 1.50 m | 59.06’’ |

| Free height | 2.10 m | 83.00’’ |

| External tunnel (tunnel B) | ||

| Free width | 1.77 m | 69.69’’ |

| Free height | 2.39 m | 94.50’’ |

| External tunnel (tunnel C in 3-part PBB) | ||

| Free width | 2.04 m | 80.32’’ |

| Free height | 2.67 m | 105.63’’ |

| Cabin ring | ||

| Internal diameter | 3.00 m | 123.50’’ |

| Service door | ||

| Width | 0.70 m | 36.00’’ |

| Height | 2.00 m | 80.00’’ |

| Front door of cabin in 2-part PBB | ||

| Free width | 1.54 m | 67.00’’ |

| Free height | 2.34 m | 93.00’’ |

| Front door of cabin in 3-part PBB | ||

| Free width | 1.54 m | 67.00’’ |

| Free height | 2.68 m | 125.25’’ |

| Canopy | ||

| Free width | 3.20 m | 135.38’’ |

| Free height | 3.02 m | 125.69’’ |

| Service stairs | ||

| Free width | 750 mm | 34.81’’ |